Single Disc Series

About Single Disc Series

In the development of our single disc row units we address many of the challenges minimum tillage farmers face. Our row units are effective at penetrating tight soils and are equally capable when faced with the sticky conditions often encountered during winter planting.

The combination of an offset and undercut disc opener allows our single disc planting units to dig effectively without requiring an over-engineered heavy frame to force the row units into the ground. To tackle the wet sticky winter conditions where stubble becomes rope bound, a combination of a simplistic low profile seed boot, floating cleaning wheel and active mud scraper system has proven to be very effective in minimum tillage operations.

Models

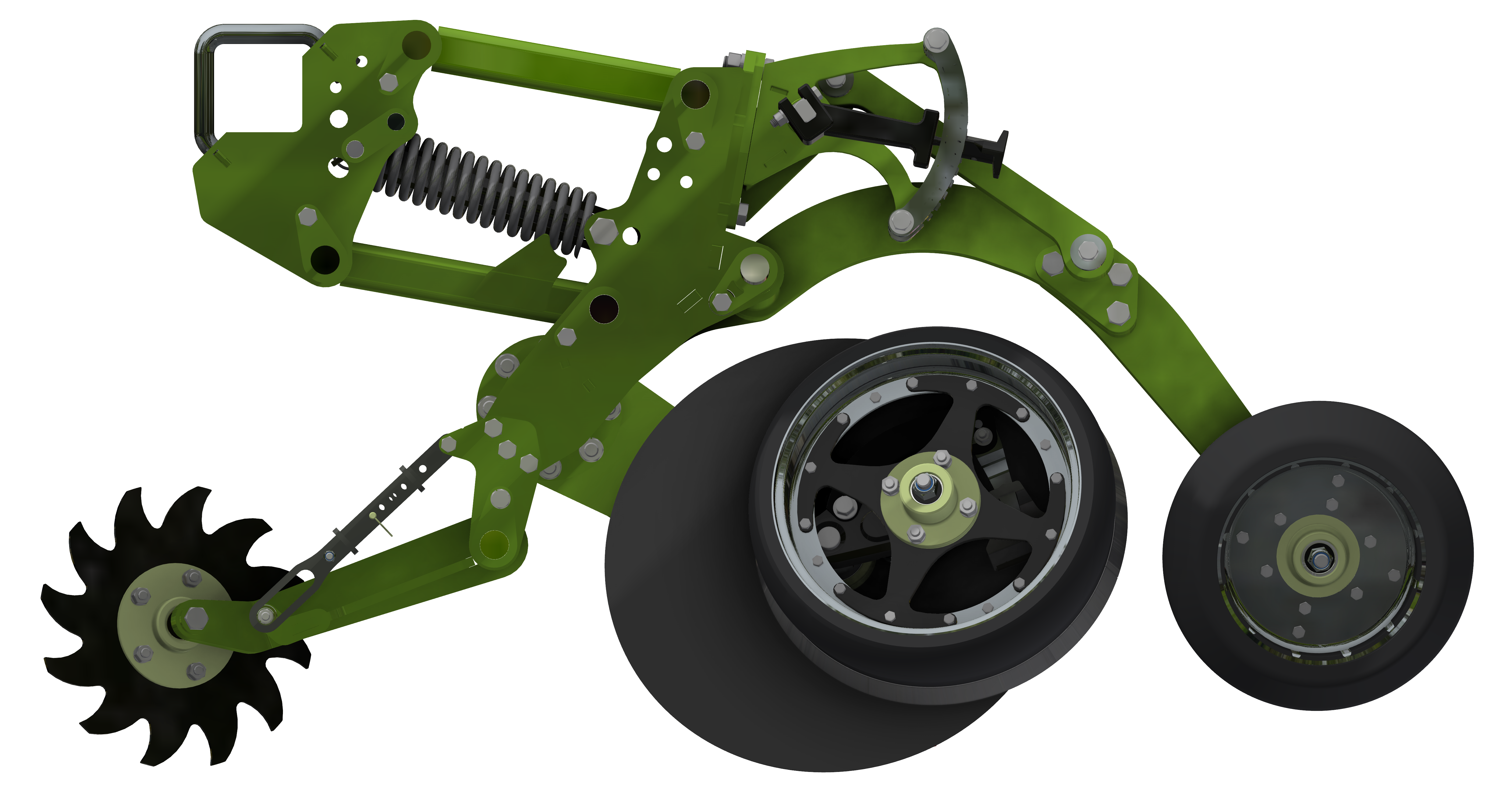

SX30S Features

Compact, fixed parallelogram design ideal for narrow row spacing.Single 20″ disc mounted on maintenance free, sealed for life double race ball bearings. Disc operates on a 21 degree undercut angle for penetrating tight soil types and minimising hair-pinning of stubble.300mm vertical travelSimple, pin-adjustable breakout pressure and seeding depth, no tools required.Rear press wheel closes the trench efficiently with minimal soil disturbance.Designed for high trash flow and tough minimum till conditions.Designed, made and owned in Australia.

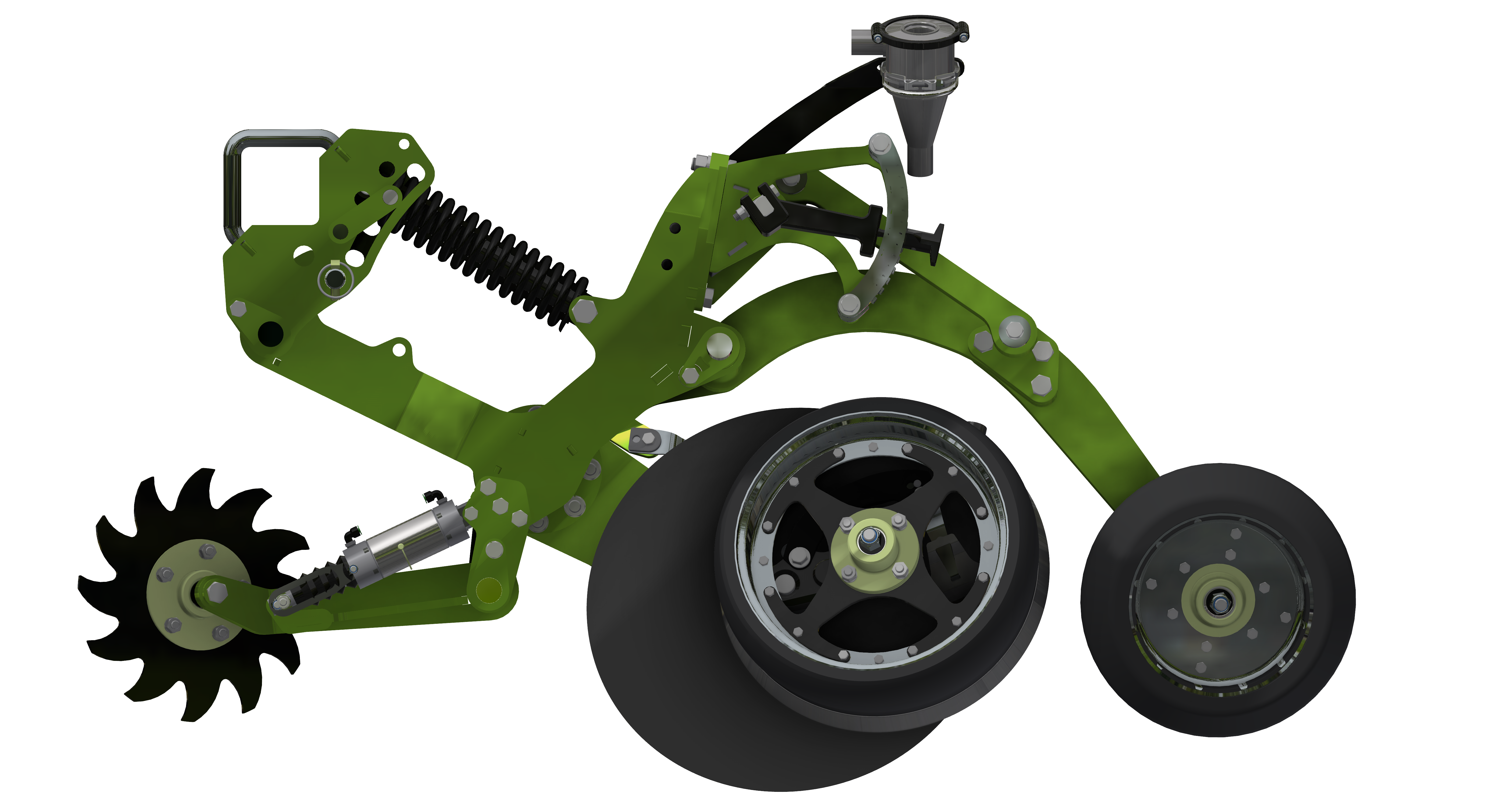

SX30P Features

Heavy-duty parallelogram design for precise depth control and superior ground following.340mm vertical travelSingle 20″ disc mounted on maintenance free, sealed for life double race ball bearings. Disc operates on a 21 degree undercut angle for penetrating tight soil types and minimising hair-pinning of stubble.Spoked cleaning wheel and active mud scraper system keep components clean and effective in sticky conditions.Hydraulic or spring downforce mechanismOptional rear press wheel options to suit various soil types and planting styles.Suited to winter crop conditions and high-residue environments.Designed, made and owned in Australia.

NX25 Features

Ideal for narrow row applications with spacing down to 300mm300mm vertical travelSimple pressure adjustments mean all pressure and depth adjustments are pin adjustable, no tools required.Single 18″ disc mounted on maintenance free, sealed for life double race ball bearings. Disc operates on a 10 degree undercut angle for penetrating tight soil types and minimising hair-pinning of stubble.Designed, made and owned in Australia,

SX30P Row Unit - Grower Testimonial

Hear from one of our NSW Growers regarding their experiences with our SX30P row unit.

Product Compatibility

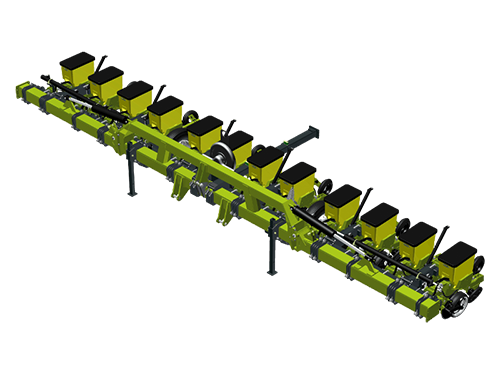

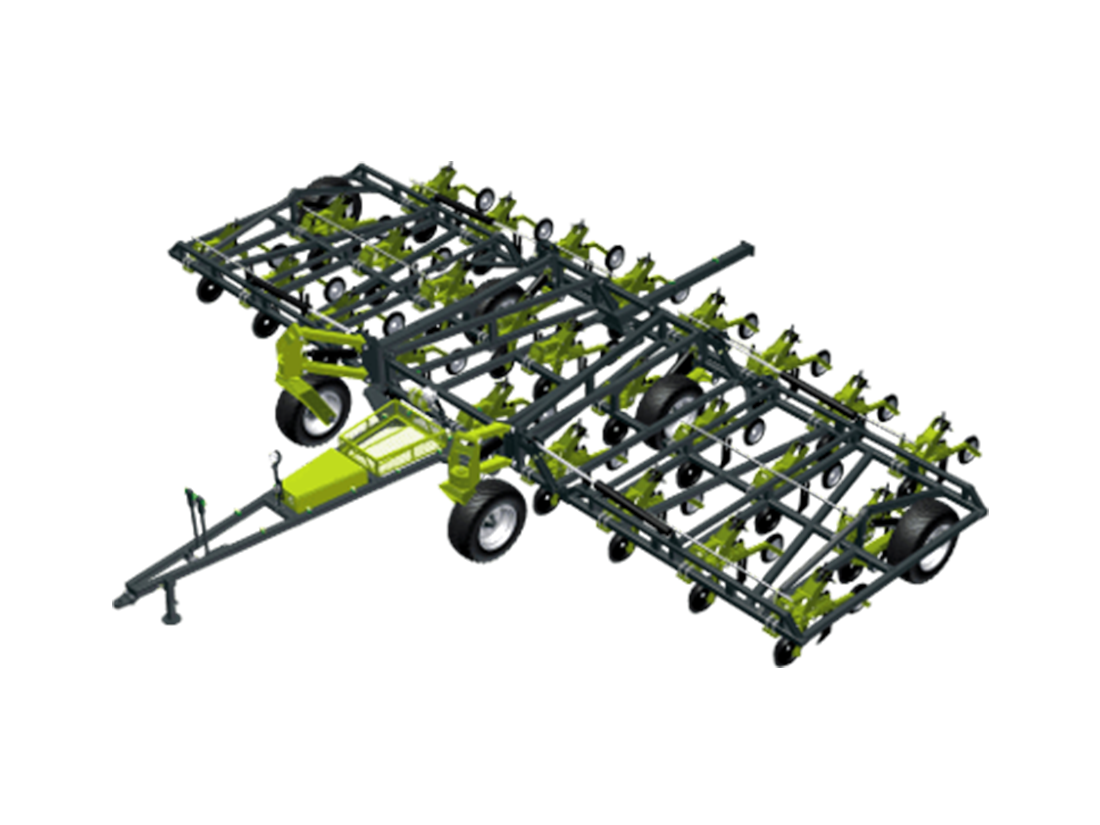

Single Bar Linkage

Our standard linkage frames are manufactured using a 200mm x 200mm RHS mainframe and a remote 100mm x 100mm RHS toolbar that the Boss range of row units bolt on to, this allows for a lot of flexibility around row spacing & wheel spacings or future changes in your farming operation.

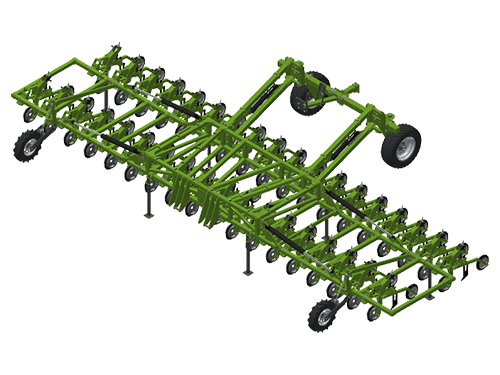

Two Bar Linkage

Our two bar linkage frames are manufactured using 100mm x 100mm RHS and allow for the fitment of all Boss row units. Two bar frames may be required for narrow spacings on disc machines or to promote stubble flow on tyne machines, they are available with lift assist or offset linkages if required.

Single Bar Trailing

Single bar frame designs are available in 3 different styles depending on your specific requirements. These frames can be configured with winter or summer seeding row units in a range of row spacings & frame widths.

Supa-Flex

The Supa-Flex (floating hitch) range of trailing planter frames from BOSS Agriculture have been developed for farmers & contractors operating in contoured, undulating or melon hole country. The supa-flex design provides greater flexibility between the tractor & implement to maximise the machines ground following ability.

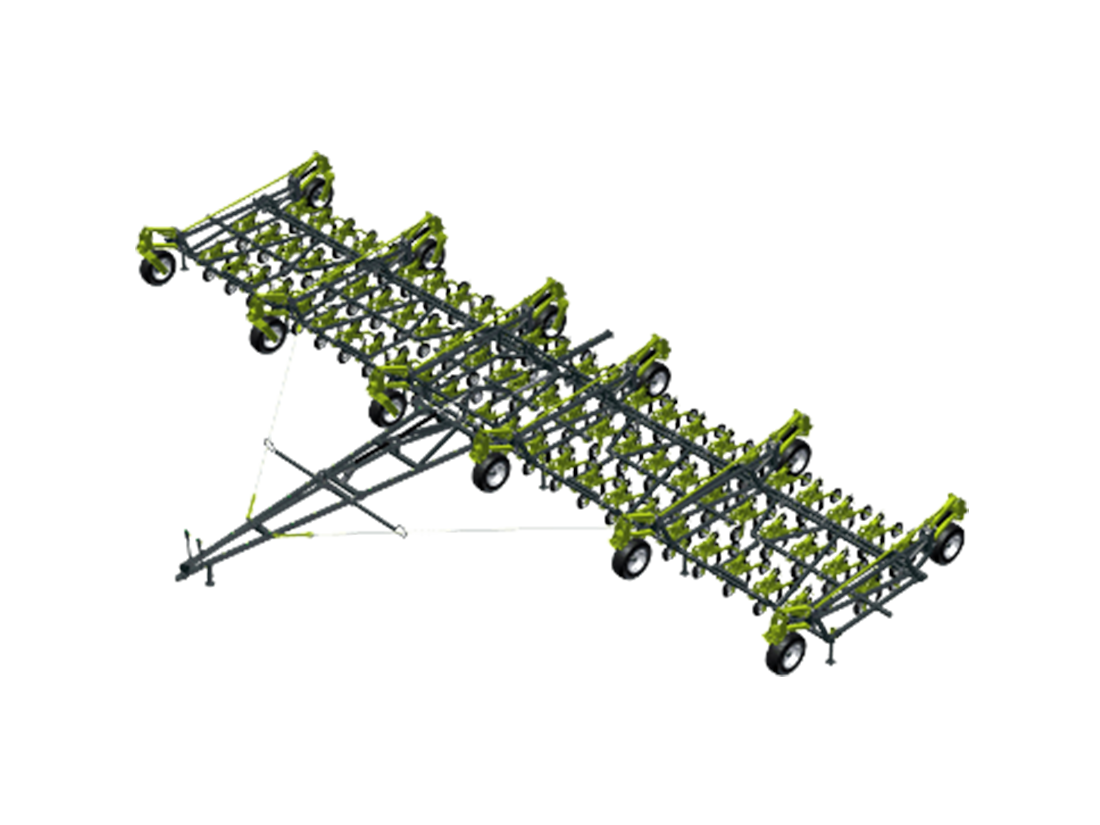

End-Tow

BOSS Agriculture’s range of end-tow (floating hitch) trailing planter frames have been developed for farmers & contractors who require wide machines and have width constraints when moving from farm to farm or shedding equipment.

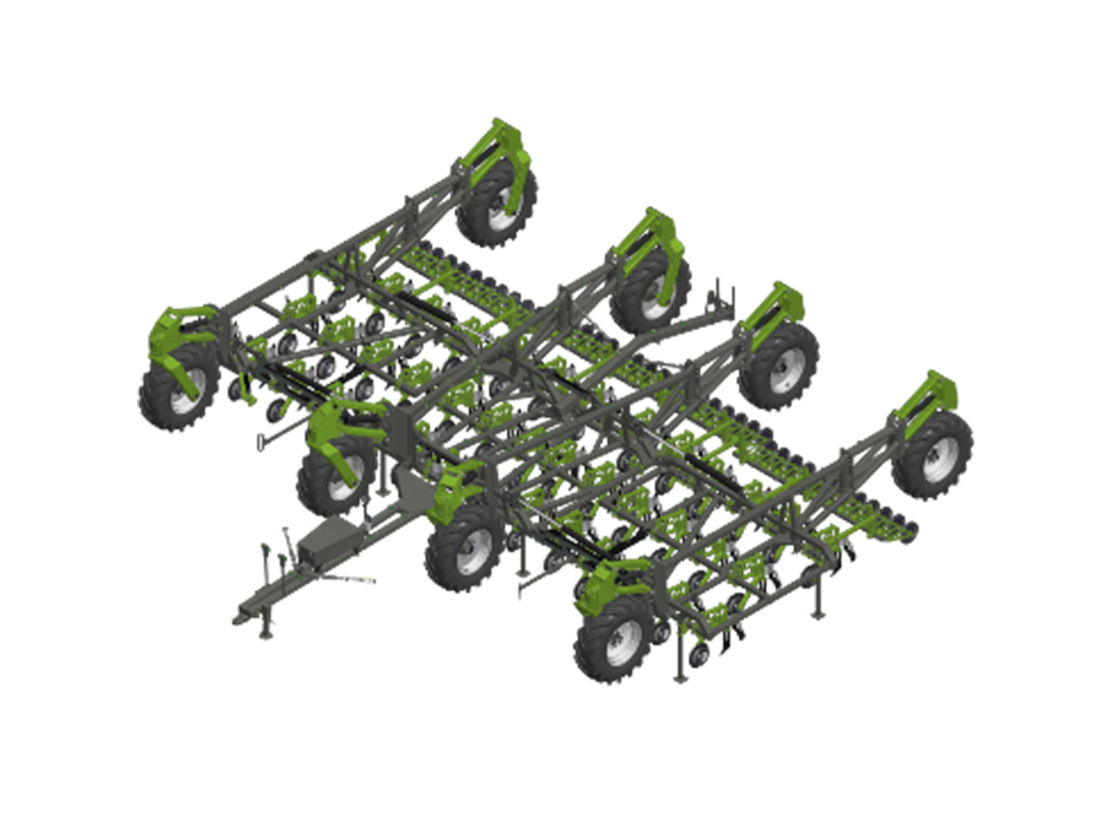

Bridge Frame

BOSS Agriculture’s Bridge (floating hitch) range of trailing planter frames have been developed to keep frame wheel assemblies outside the main frame which promotes better stubble flow and allows narrower row spacings to be achieved.