Bridge Trailing

About Bridge Trailing

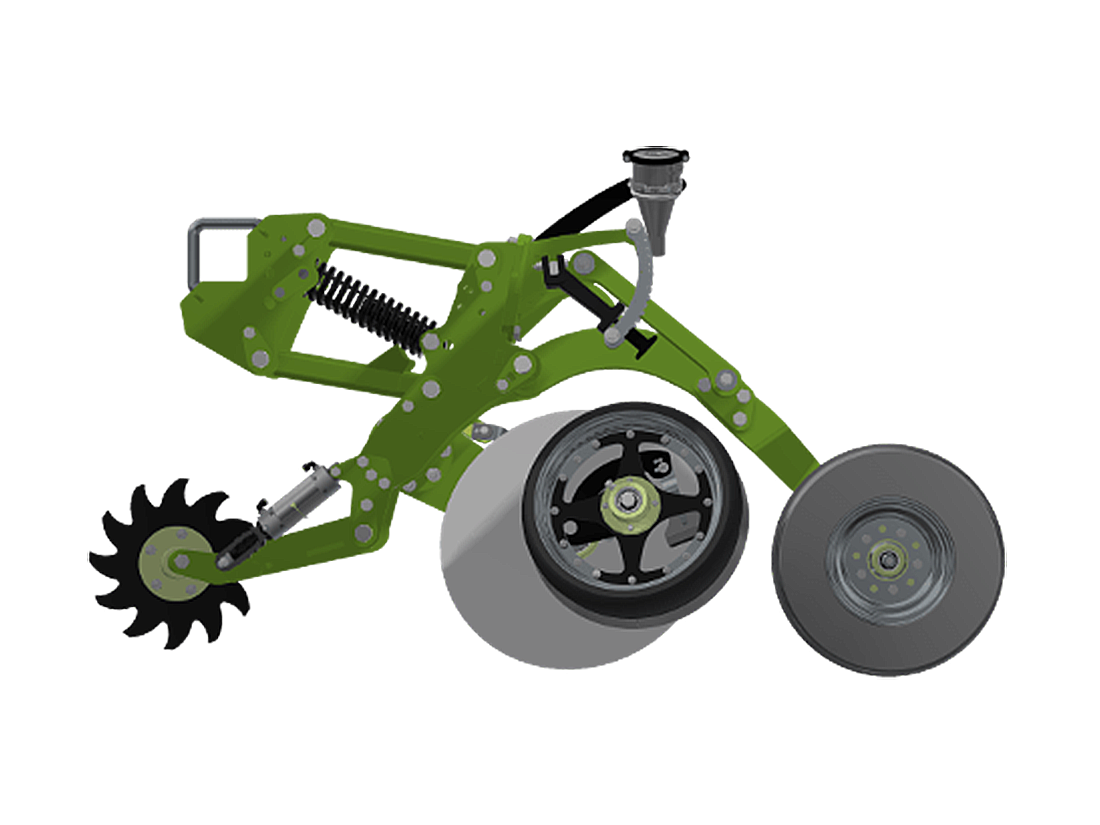

External wheels mean superior trash flow and ground floatation, and a unique flexing section gives consistent seed placement on uneven ground, while a high lift makes service and inspection easier.

Our Bridge (floating hitch) trailing seeder frames have been developed with wheel assemblies outside the main frame to promote better stubble flow on narrower row spacings.

The unique flexing centre section allows both up and down and fore and aft movement, so the frame can twist over the length of the machine, which means you can run a wider machine on uneven ground and maintain seeding accuracy. The flex design also means that frame stress and fatigue is minimised for a longer frame life.

Superior ground following ability.

This superior ground following ability allows row units to maintain an even seeding depth whilst giving constant press wheel pressure for a faster, more even crop germination. During transport the stability of the machine is greatly improved as weight is evenly distributed on all wheels.

Built to go the distance.

Bridge trailing seeder frames are constructed of 100x100x9mm RHS with plated joints on both the top and underside of the frame to ensure maximum strength and durability. The proven frame design built with experience ensures no dead weight is carried with all cross members load carrying or supportive, this allows for flexibility with row spacings. The high lift of the frame provides better access to row units for servicing and inspection of row units.

The BOSS range of bridge seeder frames is available in a variety of seeding widths (from 8 M – 24 M) and configurations including single fold and double folding designs.

Features

External frame wheels.

Rear mounted press wheel options.

Unique flexing sectional frame.

All pivots are fitted with replaceable spherical ball pivots.

Hydraulic saddles are used to carry all hoses.

Laser cut identification on drawbar end for all hydraulic hoses.

Saddle provisions for air seeder hosing.

2 stage parking jack.

Laser cut hydraulic hose keepers provided when unhitching machine.

All hydraulics hoses are protected with spiral wrap in rub prone areas.

Parking stands.

Optional toolbox, handwash tank & drawbar basket.

Australian designed, made and owned.

Dig into the details.

From specs to standout features – get the full picture in our product brochure.

Product Compatibility

Precision Tyne Series

BOSS Agriculture’s Precision Tyne Series sets the standard in broadacre seeding, designed from experience to deliver a seeding unit that is accurate, tough and simple to operate and maintain.

Single Disc Series

In the development of our single disc row units we address many of the challenges minimum tillage farmers face. Our row units are effective at penetrating tight soils and are equally capable when faced with the sticky conditions often encountered during winter planting.